What You Need to Know About Crusher Types

Release time: 2025-09-30

In modern industrial production, crushers are widely used in industries such as mining, construction, metallurgy, chemicals, and sand making. Their primary function is to break large materials into the required size for subsequent processing or utilization. Crushers come in a wide variety of types, depending on their operating principles and application scenarios. This article will introduce several common crusher types to help you understand the equipment that best suits your production needs and select the most suitable crusher.

1.Jaw Crusher

The jaw crusher is one of the most common crushing equipment, widely used in industries such as mining, construction, metallurgy, and chemicals. Its main feature is the compression and crushing of materials through the reciprocating motion of two jaw plates.

- Applicable Materials: Large, hard ores, rocks, and construction waste.

- Advantages: Simple structure, reliable operation, easy maintenance, and high processing capacity.

- Applications: Commonly used in the coarse crushing stage, suitable for processing hard ores and large stones.

2. Impact Crusher

An impact crusher utilizes impact energy to crush materials with a medium hardness or lower. Its operating principle is that the material is struck by impact plates on the high-speed rotating rotor and then rebounds into the crushing chamber for secondary crushing.

- Applicable Materials: Medium-hard materials such as limestone, coal, gypsum, and slag.

- Advantages: High crushing ratio, high processing capacity, and good finished product particle size.

- Applications: Widely used for secondary crushing in industries such as building materials, chemicals, coal, and mining.

3. Cone Crusher

A cone crusher uses rotational motion to crush materials. Its operating principle is that the interaction between the fixed and rotating cones causes the material to be continuously compressed and squeezed, achieving a crushing effect.

- Applicable Materials: Harder ores and stones, such as granite and basalt.

- Advantages: High adaptability, uniform finished product particle size, and easy maintenance.

- Applications: Widely used in secondary or tertiary crushing, especially for fine and ultra-fine crushing operations requiring precise particle size.

4. Hammer Crusher

A hammer crusher uses high-speed rotating hammers to impact materials, crushing them. Its operating principle is that after entering the crushing chamber, the material is gradually broken down by the impact of the hammers. It is suitable for soft to medium-hard materials.

- Applicable Materials: Coal, gypsum, limestone, and other low-to-medium-hardness materials.

- Advantages: Compact structure, simple operation, and low investment.

- Applications: Suitable for small crushing lines, especially for low-hardness materials such as coal and limestone.

4. Vertical Crusher

A vertical crusher is a highly efficient crushing device that primarily crushes materials through the collision and impact of a high-speed rotating rotor. It has excellent particle shaping capabilities, making it ideal for sand making and shaping.

- Applicable Materials: Quartz, granite, basalt, construction waste, etc.

- Advantages: Excellent crushing effect, excellent finished particle shape, and adjustable fineness.

- Applications: Widely used in sand and gravel yards, artificial sand making, mining, and other industries.

6. Double-Stage Crusher

The double-stage crusher features a dual-rotor design and is suitable for crushing materials with high humidity and difficult to handle. Its greatest feature is that it can reduce materials to a smaller particle size in a single crushing process.

- Applicable Materials: Clay, coal slime, slag, and other materials with high humidity.

- Advantages: Highly efficient crushing, avoids clogging problems associated with traditional crushers, and has strong adaptability.

- Applications: Widely used in industries such as coal mining, metallurgy, and building materials, and is particularly suitable for handling materials with high humidity and difficult to handle.

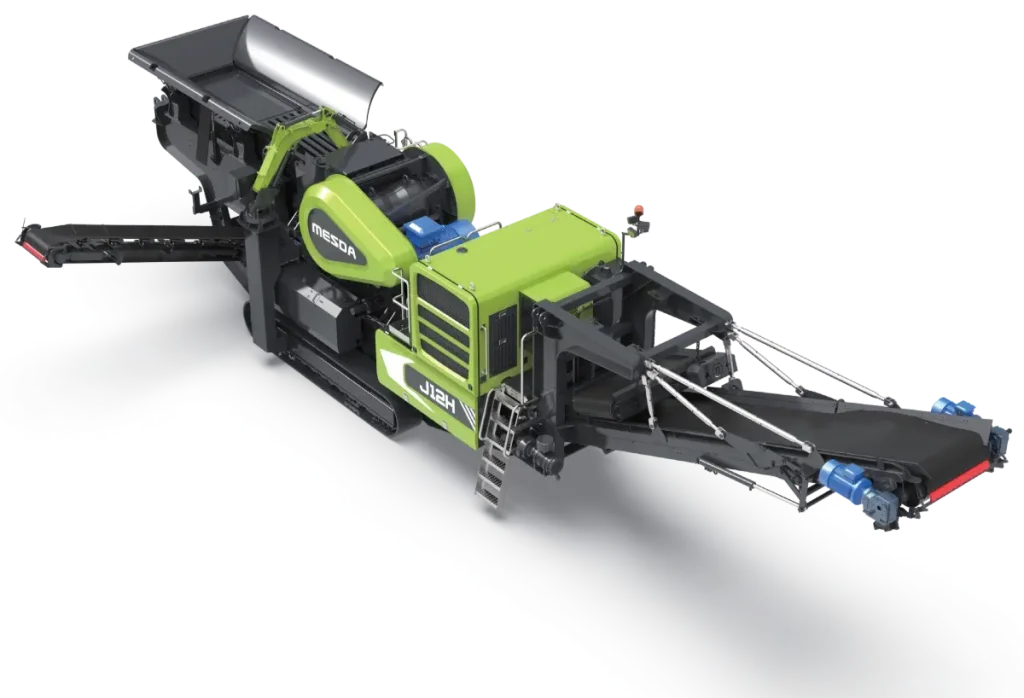

7.Mobile Crusher

A mobile crusher is a device that can be used for on-site crushing and offers high mobility. It is suitable for crushing operations that require frequent changes in working locations, such as mines, construction sites, and roads.

Applicable Materials: Almost all types of ores, waste, and construction waste. Advantages: High mobility, flexible operation, and reduced transportation costs.

Applications: Suitable for crushing tasks that require frequent relocation, such as construction waste and mining operations.

Considerations for Selecting a Crusher

When choosing a crusher, you need to select the appropriate equipment based on your production needs, material properties, crushing objectives, and production capacity. Here are some factors to consider when selecting a crusher:

- Material hardness and properties: Different types of crushers are suitable for materials of varying hardness and properties.

- Production capacity: Choose a crusher with the appropriate processing capacity based on your production scale and needs.

- Finished product particle size requirements: If you require a specific particle size, choose a crusher with adjustable particle size.

- Maintenance and maintenance: Ease of maintenance and cost are important considerations when selecting a crusher.

Conclusion

Crushers, as heavy machinery, play a vital role in various industries. Choosing the right crusher not only improves production efficiency but also effectively reduces maintenance costs. We offer a wide range of crushers to meet the needs of different customers, helping you improve production efficiency and reduce operating costs.

If you are looking for efficient and durable crusher equipment, please contact us and we will provide you with the most suitable crusher solution based on your specific needs!